MasterSeries Blog

Integrated design of cellular beams and web openings

Using a cellular beam is one of the most popular ways to increase load capacity, to save weight and to create an economic structure. But, in most cases, the design of these beams are carried out with separate programs and design charts.

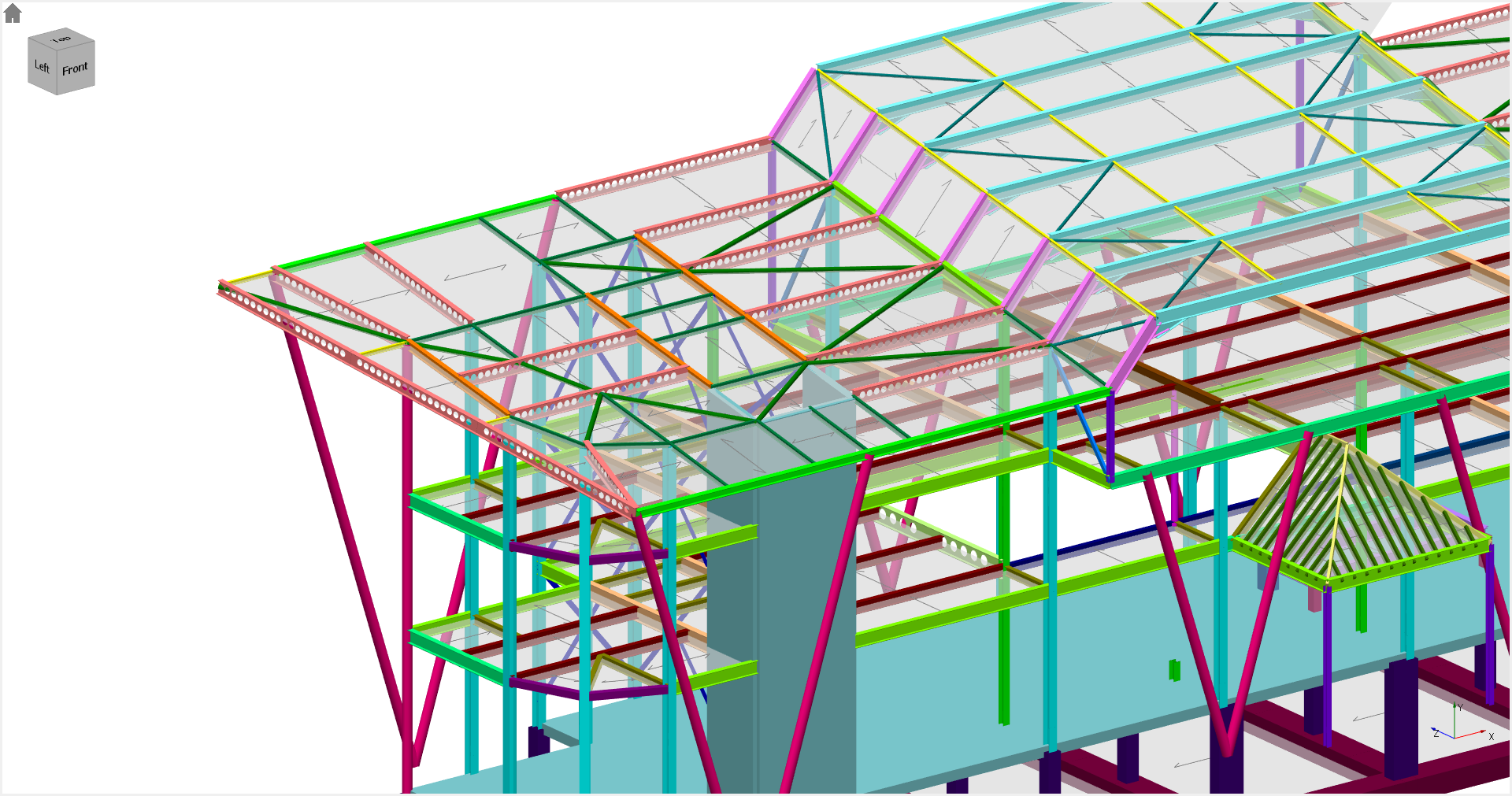

In MasterFrame analysis and design software, the cellular beam is an integrated part of the whole 3D structural model and design process.

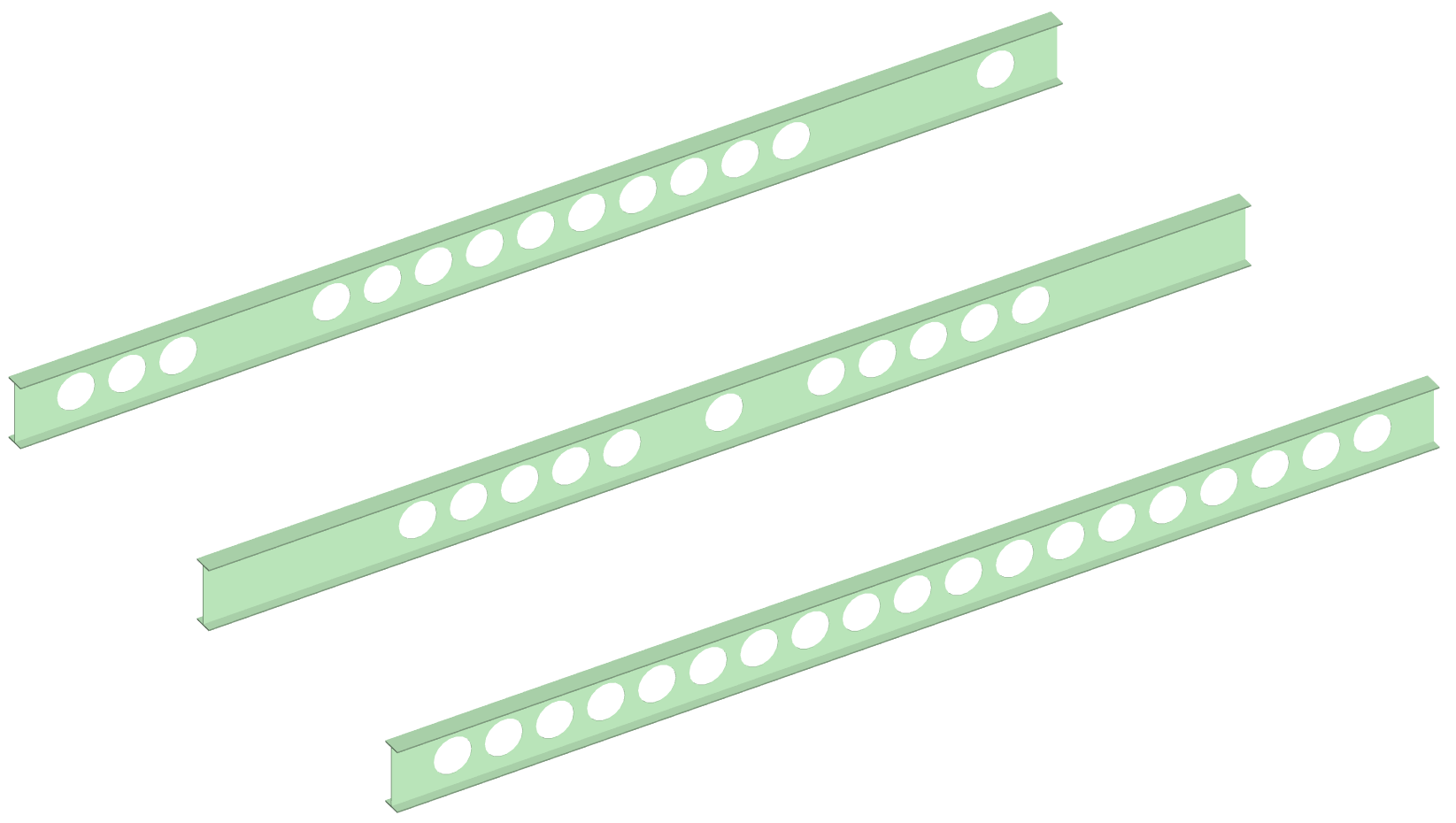

Both hot rolled I and H section, such as UB or UC or European IP or HE, and built-up I sections can be used to create cellular beams. The smart handling of cellular beams, in case of the hot-rolled sections, automatically updates the height of the section (and of course the section properties) according to the cellular hole diameter and the manufacturing requirements.

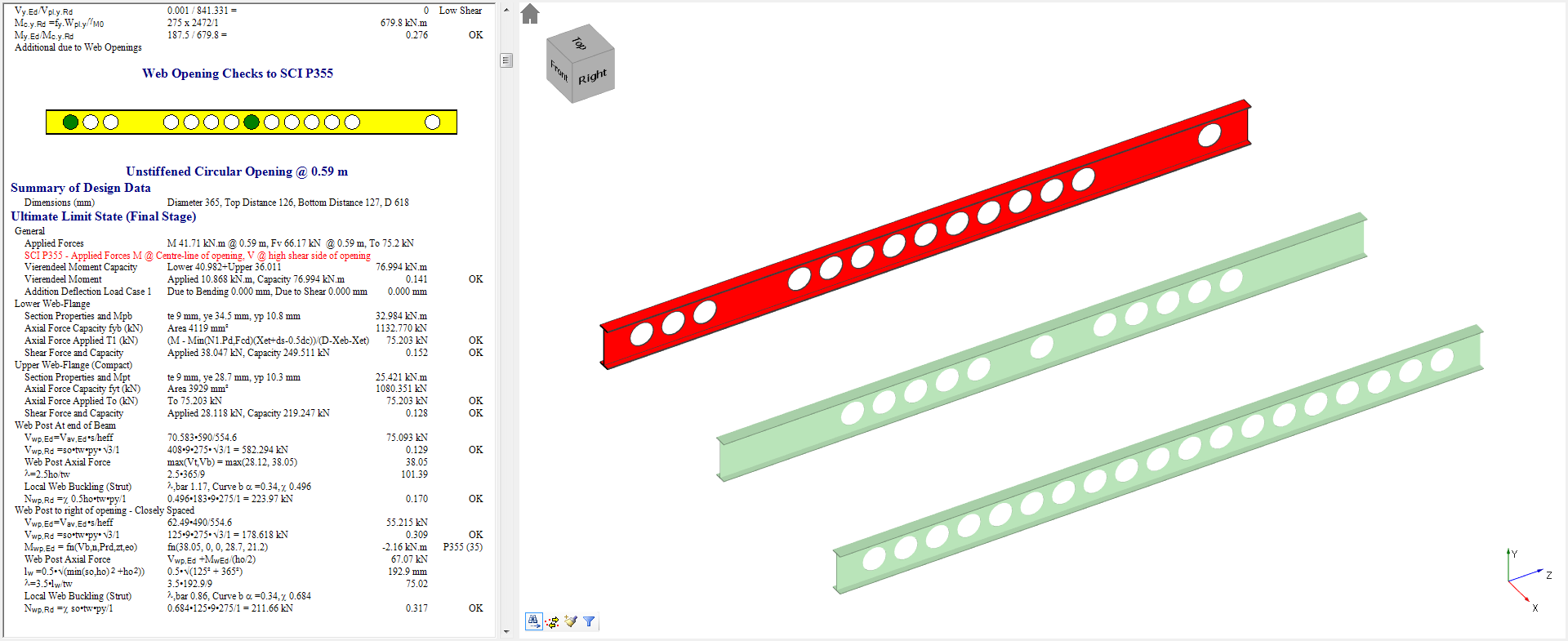

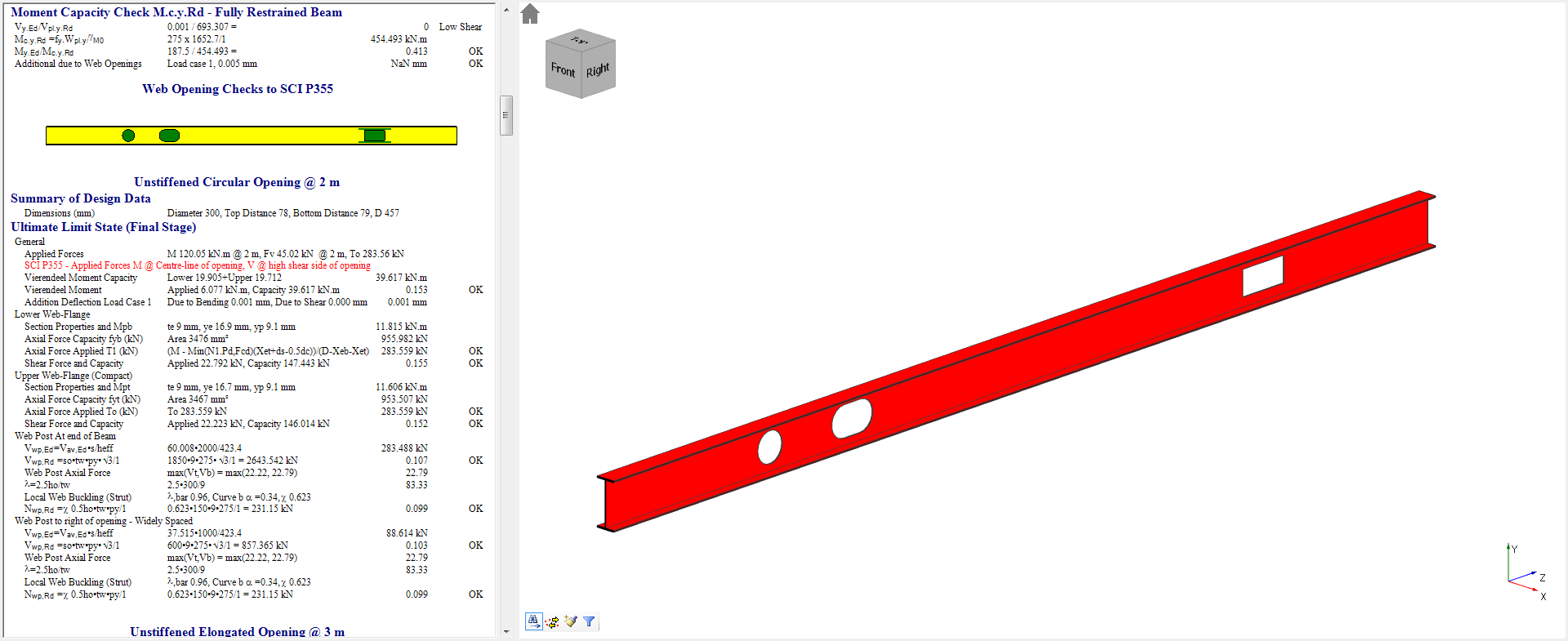

MasterFrame handles the filling of discrete web opening as well, to allow for concentrated loads or high shear forces.

During the analysis, in case of the cellular beam, MasterFrame automatically modifies the section’s inertia to accuratly calculate the correct deflection and internal forces.

The design procedure automatically recognises the actual cellular beam configuration and accordingly apply the design methods.

With MasterFrame we are not only able to model and design the cellular beams with even circular openings, but we can place arbitrary positioned discrete web openings as well.

Opening’s can be circular, elongated or even rectangular.

In the design interface, you can add additional stiffeners around the web opening to improve the strength of the residual Tee section in resisting the Verendeel forces.

Explore how MasterSeries can help you design more economical solutions and boost your productivity.

Try it for yourself with a free 14-day trial.

Categories

- About

- Beam Designer

- BIM

- Composite design

- Concrete Design

- Connections

- Dynamic

- Educational

- General

- LCA

- Masonry

- MasterFrame

- Pile Cap

- Portals

- PowerPad

- Retaining wall

- Steel Design

- Webinar

- Wind Analysis