MasterSeries Blog

The effect of fastener holes' on the design resistance of steel members

To form structural steel joints, in most cases, we use bolts and fasteners, which require holes in the steel members.

MasterSeries' MasterKey Moment & Simple Connections both check connections for net tensile areas. However the connections are frequently designed by the steel fabricator, particularly bracing connections. It is vital that the design engineer considers the effect of bolt holes in the origonal member design.

How can we take into account the effect of fastener holes in the steel member design?

In Eurocode 3, between certain limits, you are allowed to neglect the effect of the fastener holes in steel member design, except in calculating tension resistance (EN 1993-1-1, section 6.2.3).

To calculate the cross-section properties with holes, the Eurocode 3 distinguishes between gross cross-section, which is determined based on the nominal section dimensions, and net cross-section, which is determined with the deduction fo the holes.

For cross-section with holes, the Eurocode 3 defines the tension resistance as the smaller of:

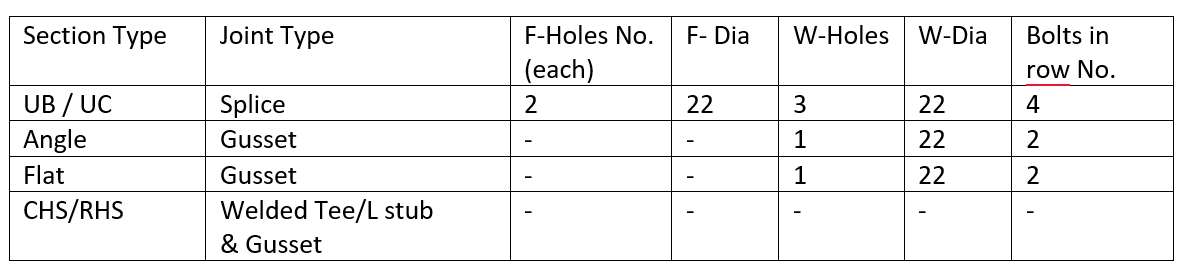

a) The plastic resistance of the gross cross-section

Note: Yield stress and Gamma M0 For S275 this give = A x 275/1 = 275 A

b) The ultimate resistance of the net cross-section at holes

Note: Ultimate stress and Gamma M2 For S275 this give = 0.9 Anet x 430/1.25 = 310 Anet

For angles, which are connected unsymmetrically through one leg, EN1993-1-8, section 3.10.3 provides more detailed consideration.

Example

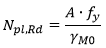

In our following example, we will show how the tension resistance of the bracing system members change due to the fastener holes.

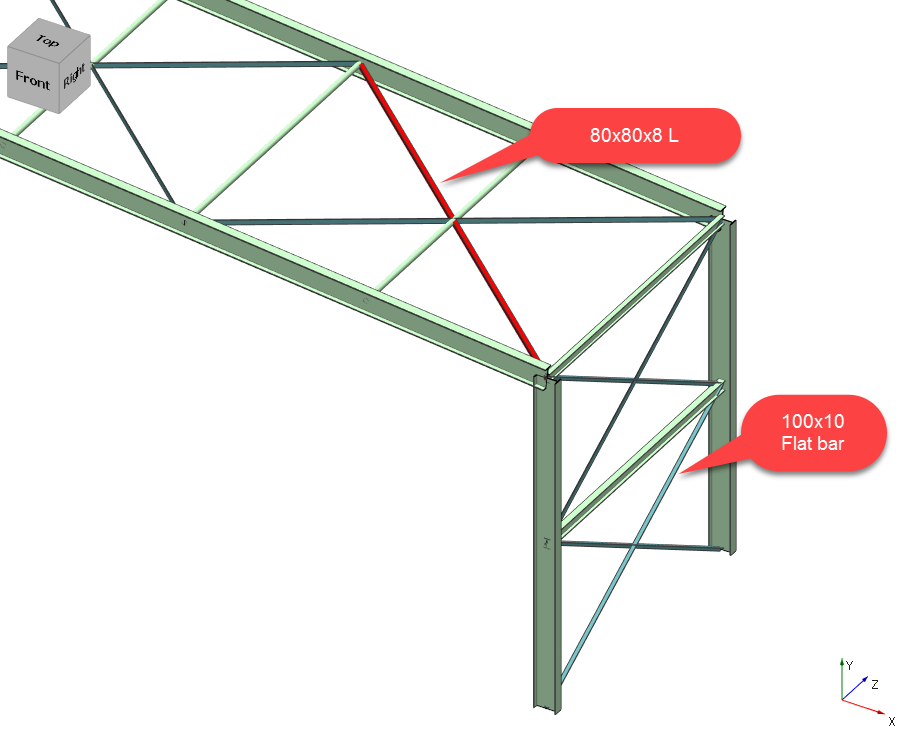

- 80x80x8 L (S275):

NEd= 49.51 kN

- 100x10 Flat (S275) bar:

NEd= 108.71 kN

Calculating the same frame in MasterSeries we get the same tension resistance.

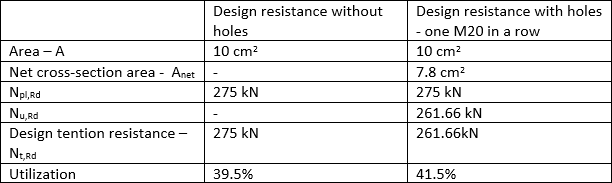

Typical input for Strut & tie member design

As CHS/RHS members have a Tee or L-plate stub welded to the end of the member, and this is then bolted to a gusset plate, there is no reduction in the member's tensile capacity.

Explore how MasterSeries can help you design more economical solutions and boost your productivity.

Try it for yourself with a free 14-day trial.

Categories

- About

- Beam Designer

- BIM

- Composite design

- Concrete Design

- Connections

- Dynamic

- Educational

- General

- LCA

- Masonry

- MasterFrame

- Pile Cap

- Portals

- PowerPad

- Retaining wall

- Steel Design

- Webinar

- Wind Analysis